Why Structural Steel Is Replacing Concrete in Large-Scale Industrial Projects

Material choices in industrial construction are no longer based on habit. Across factories, warehouses, power plants, and logistics facilities, decisions are increasingly shaped by delivery timelines, operational demands, and how buildings are expected to perform years after completion. In many cases, these factors are pushing projects away from concrete and toward structural steel.

This shift is not driven by preference alone. It reflects how industrial projects actually run today. Schedules are tighter. Expansion is expected. Downtime is expensive. In regions with established production and export capability, including structural steel fabrication in UAE, steel construction has become a more workable option for large-scale industrial development.

Time on Site Matters More Than Ever

On industrial projects, time lost on site is rarely recovered elsewhere. Concrete construction depends heavily on sequence. Formwork, reinforcement, pouring, curing—each step waits for the previous one to finish. Weather, site conditions, and labour availability all affect progress.

Structural steel changes that equation. Foundations can move ahead while steel is fabricated elsewhere. When materials arrive, erection progresses quickly and with fewer dependencies. For facilities where commissioning dates affect production or logistics operations, this difference matters.

This approach is supported by structural steel fabrication in UAE, where controlled production environments and planned delivery schedules help reduce uncertainty during construction.

Buildings That Can Change Without Major Disruption

Industrial buildings are rarely final at handover. Equipment layouts change. Storage needs increase. Additional lines or platforms are added. Concrete structures can accommodate change, but often at high cost and disruption.

Steel structures allow more flexibility. Clear spans reduce internal constraints. Structural modifications can be planned and executed without extensive demolition. Extensions and mezzanines are easier to integrate when the original structure allows for it.

This is one reason developers increasingly rely on systems supported by structural steel fabrication in UAE, where detailing accuracy makes future adjustments more manageable.

Performance Under Industrial Conditions

Industrial environments place continuous demands on structures. Heavy machinery, crane movements, vibration, and dynamic loading are part of daily operation.

Structural steel handles these conditions well. Its strength in both tension and compression supports long spans and high-bay configurations. Behaviour under wind and seismic forces is predictable, which simplifies design and long-term performance assessment.

Quality Control Away From the Jobsite

On-site concrete work is influenced by many variables—weather, workmanship, supervision, and curing conditions. These factors can differ from one project to the next.

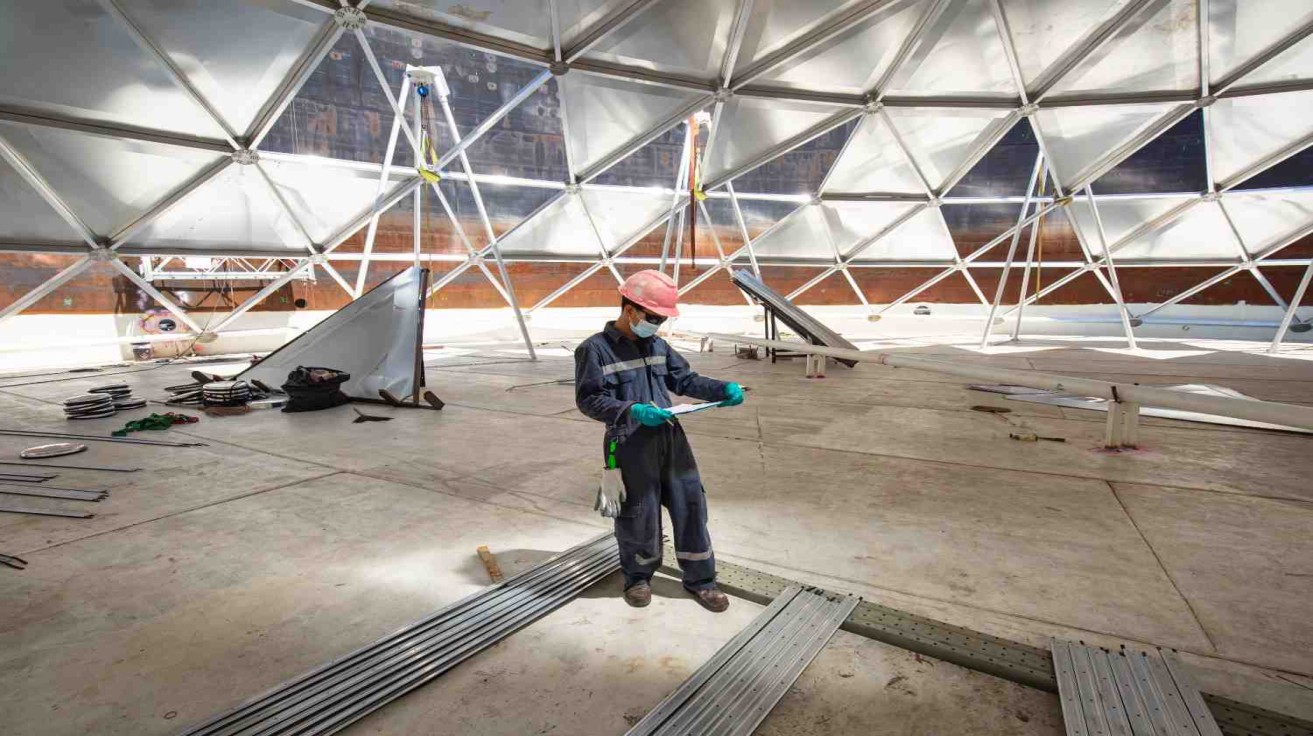

Steel fabrication shifts critical work away from site. Components are produced under controlled conditions, inspected before delivery, and assembled according to defined tolerances. Fewer variables mean fewer surprises during erection.

With structural steel fabrication in UAE, this controlled process supports consistent output and smoother coordination with inspectors and consultants.

Fewer Unknowns in Cost and Programme

Concrete often appears economical at first glance. In practice, extended site durations, labour exposure, and rework can push costs beyond initial estimates.

Steel construction offers clearer parameters. Quantities are fixed earlier. Fabrication schedules are defined. Erection windows are shorter. Reduced dependency on site conditions helps limit unplanned delays.

For projects where predictability matters, working with experienced providers of structural steel fabrication in UAE helps align cost, schedule, and execution more closely.

Sustainability and Digital Compatibility

Sustainability requirements are now standard on industrial projects. Structural steel supports these objectives through recyclability and efficient material use. Off-site fabrication also reduces waste and improves material control.

Steel integrates well with digital construction workflows. BIM-based coordination allows design conflicts to be resolved early, reducing site-level issues and improving overall execution.

Conclusion

The replacement of concrete with structural steel in large-scale industrial projects reflects how construction priorities have changed. Speed, adaptability, quality control, and long-term performance now influence material decisions more than tradition.

As industrial facilities continue to grow in size and complexity, solutions backed by structural steel fabrication in UAE are increasingly shaping how these projects are delivered. For many developers, structural steel is no longer a secondary option—it has become the practical baseline.