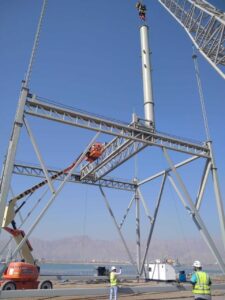

Erection Of Steel Structures

Erection of Steel Structures The erection of steel structures plays a major role in modern construction; it involves the assembly of several steel components that are secured together on-site to create a strong, stable framework that supports buildings, factories, warehouses, and industrial facilities.

With years of experience, Kingston Technical Contracting LLC has earned a reputation for reliability and expertise in the field. Kingston Technical Contracting LLC is known for bringing the best steel structure erection services in Dubai. We deliver every project executed with maximum efficiency and safety through a focus on combining precision engineering, advanced machinery, and skilled manpower. We ensure the implementation of effective site security policies to meet both local and personal security requirements, thereby reducing the chances of accidents and delays caused by poor and unsafe site conditions and easing an efficient construction process.

Our steel structure erection process keeps international standards and includes every stage of construction, from careful planning and timely delivery of components to accurate positioning and secure connection through bolting or welding, and we make sure each component is carefully aligned to guarantee structural strength while staying on timeline and maintaining our quality standards from the starting stage of project coordination to the final handover. We focus on reducing risks, boosting productivity, and delivering affordable solutions that go beyond what our clients expect.

The thing that really makes our service stand out is how seriously we take quality and safety, which is exactly the reason why choosing Kingston Technical Contracting LLC should be your trusted partner for structured steel erection.

Our service extends beyond erection. Being a leading steel fabrication company in UAE, we can take care of everything for you—fabrication design, detailing, erection, and finishing—eliminating the hassle of coordinating multiple contractors. Behind every project is our experienced team of engineers, supervisors, and technicians who know that good communication and organized site management make all the difference. We consistently deliver structures on time, on budget, and built for the long haul. We’ve built up quite a reputation with successful projects all across Dubai and the UAE. Our focus remains on delivering steel erection solutions that are safe, efficient, and built to last—helping drive the growth of industries and infrastructure throughout the region.