How to Evaluate and Choose a Top Structural Steel Fabrication Company in Saudi Arabia

Structural steel isn’t just another construction material in Saudi Arabia—it’s literally holding up the Kingdom’s most ambitious projects. NEOM‘s cutting-edge developments, the Red Sea Global transformations, and entire new districts rising from the desert—all of them depend on steel fabrication that can’t afford to fail.

Vision 2030 has created massive opportunities, but it’s also raised the stakes. Finding the right structural steel fabrication company matters more than ever, and the decision goes way beyond comparing price quotes or scanning through glossy brochures.

Choose poorly, and projects face delays that cascade through schedules. Quality issues emerge on-site. Safety concerns appear. Budgets balloon. None of these are theoretical risks—they happen when fabrication partners can’t actually deliver what they promised.

The fabricators worth partnering with bring together precision engineering, operational systems that actually work under pressure, internationally recognized certifications, and a real understanding of how complex projects get executed in the real world.

So what should teams look for when evaluating structural steel fabrication companies in Saudi Arabia? Here’s what actually matters.

Does Their Project History Match Your Requirements?

Past performance tells the real story. The fabricators worth serious consideration have handled genuinely demanding projects—not just standard commercial buildings, but developments requiring both technical precision and complex architectural coordination.

When reviewing potential partners, their portfolio needs scrutiny. What types of projects have they completed? Did those projects demand the kind of accuracy and coordination your development requires?

Take fabricators who’ve worked on major UAE projects like The Royal Atlantis Resort, Guggenheim Abu Dhabi, Zayed National Museum, or Uptown Dubai Phase 1. These weren’t simple structures. They required serious technical capability, tight coordination with international design teams, and flawless execution under demanding timelines.

That kind of background demonstrates something valuable—the ability to handle intricate designs, maintain precision when schedules get tight, and coordinate effectively with global consultants and contractors. Saudi Arabia’s high-specification construction environment demands exactly these capabilities.

Certifications That Demonstrate Real Standards

In the steel fabrication industry, certifications separate serious operators from companies just trying to win bids. For Saudi Arabia projects, international and regional standards aren’t checkboxes—they’re fundamental to how work gets done.

Certificates to verify:

ISO 9001:2025 – This Quality Management certification means the company follows consistent, documented processes across all fabrication operations. It’s not just about having procedures written down somewhere; it’s about actually following them.

ISO 45001:2018 – Health and safety standards matter enormously in fabrication facilities. This certification shows structured approaches to protecting workers and maintaining safe operations.

ISO 14001:2015 – Environmental management isn’t optional anymore. This certification confirms sustainable practices are built into fabrication, coating, and finishing processes, not added as afterthoughts.

Saudi Commercial Registration and Municipal Licensing – Operating legally within the Kingdom requires a valid KSA trade or commercial registration. Sounds basic, but it’s worth verifying.

GCC Regional Presence – Fabricators with established operations across the Gulf—holding UAE trade licenses in Dubai, Sharjah, or Abu Dhabi alongside Saudi registrations—can manage regional projects more smoothly. They understand cross-border logistics and regulatory requirements in practical terms.

These certifications confirm something important: the company operates under structured, audited systems from material procurement through final delivery. Everything meets both international standards and Saudi regulatory requirements, including SBC, SASO, and SABER compliance.

What Can They Actually Control In-House?

Here’s a reality check: what a structural steel fabrication company controls internally determines how reliably they deliver. Heavy reliance on subcontractors creates coordination gaps, quality inconsistencies, and accountability questions.

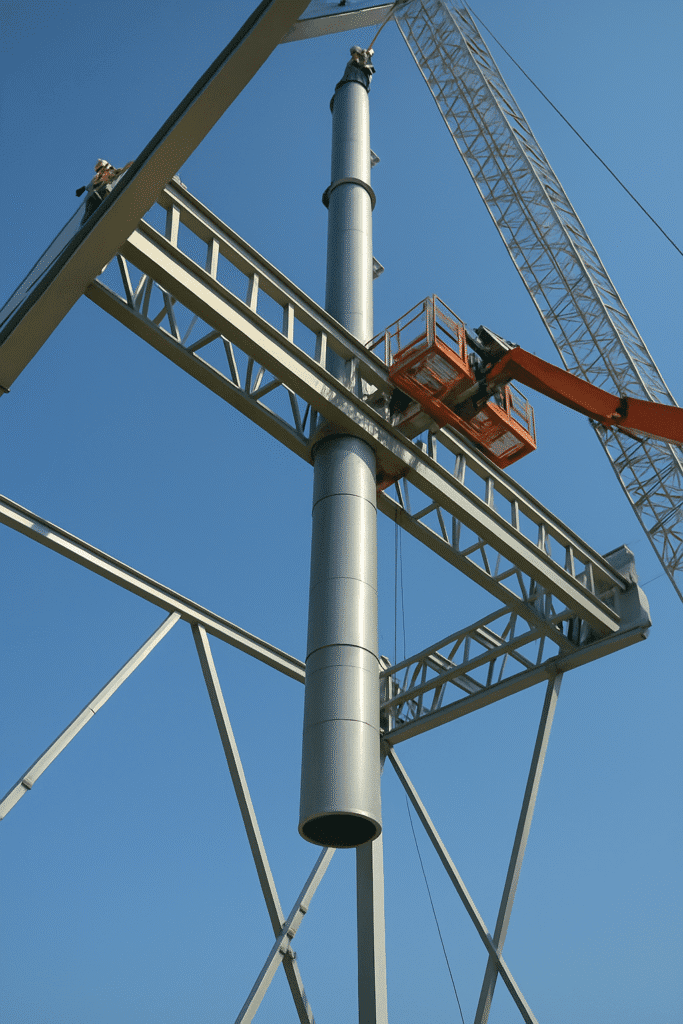

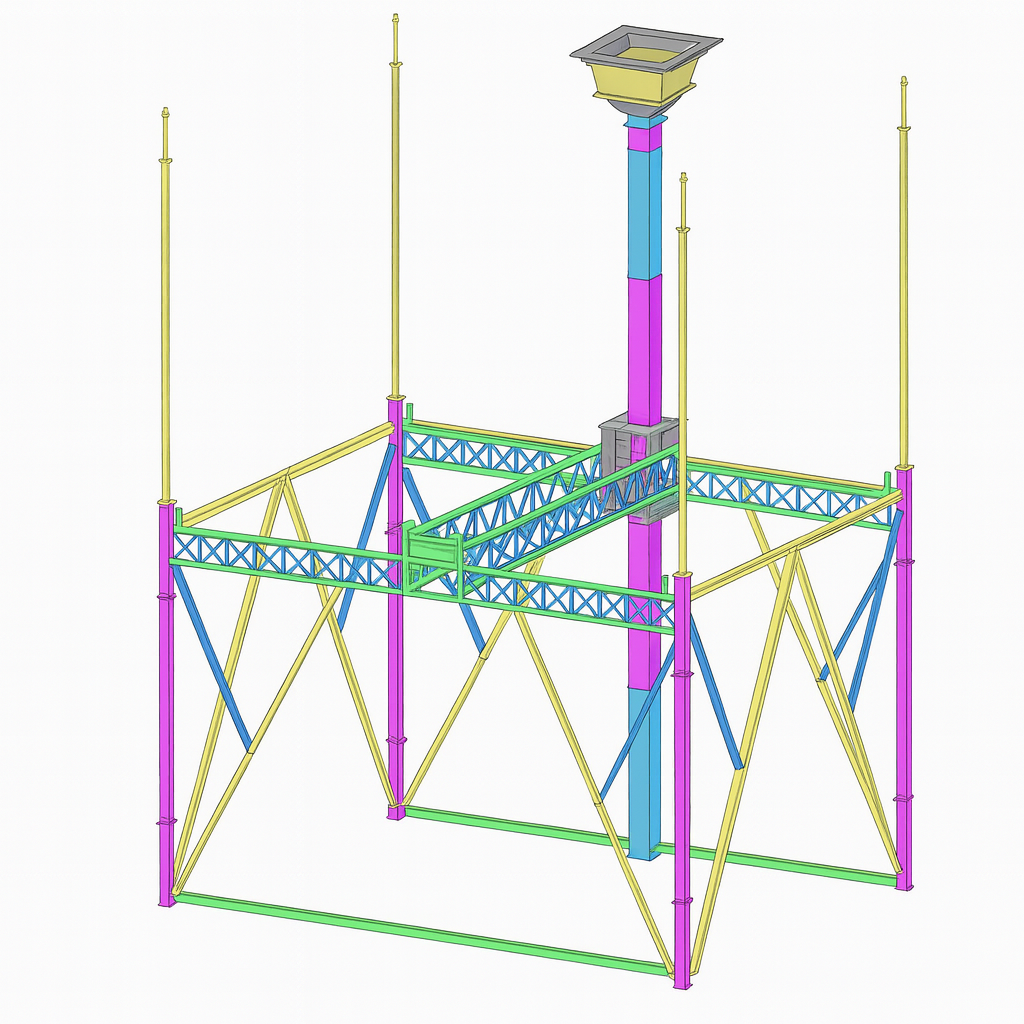

Strong fabricators maintain comprehensive in-house capabilities:

- Design and 3D modeling using Building Information Modeling (BIM) systems

- Connection detailing with CNC precision cutting

- Automated welding systems backed by thorough NDT inspection

- Surface treatment and coating in controlled facility environments

- End-to-end logistics coordination and installation oversight

This vertical integration matters in practical terms. Fewer handoffs mean fewer delays. Clear ownership means accountability. Problems get addressed faster because everything stays under one operational umbrella. In Saudi Arabia’s fast-moving construction market, where schedule slips and quality deviations carry real financial consequences, this integration provides significant advantages.

How Do They Actually Ensure Quality?

Quality control either runs through a company’s culture or it doesn’t. Marketing materials all claim rigorous standards, but the real question is what systems actually operate day-to-day.

Established fabricators implement specific practices:

- Material traceability from mill certificates through final delivery

- Inspection checkpoints at every critical fabrication stage

- Non-Destructive Testing protocols verifying weld integrity and structural soundness

- Safety management systems aligned with international standards, not just local minimums

These aren’t bureaucratic procedures for the sake of paperwork. They prevent expensive rework downstream, reduce construction site risks, and ensure delivered components arrive ready for installation rather than requiring field corrections that eat up schedules.

Communication Makes or Breaks Execution

State-of-the-art fabrication equipment doesn’t mean much if communication falls apart. Projects succeed or struggle based largely on information flow between the fabricator and the client.

Professional operations assign dedicated project managers who provide regular, meaningful updates—where fabrication stands, what’s shipping when, and any concerns before they turn into problems.

Transparent documentation, proactive updates, responsive coordination when issues arise—these aren’t nice-to-have extras. They’re what separates smooth project execution from constant firefighting and schedule surprises.

Understanding Real Value vs. Just Low Pricing

Cost efficiency goes beyond accepting the lowest number on a bid sheet. It’s about understanding the relationship between price, quality, and reliability over the project lifecycle.

Reputable structural steel fabrication companies break down costs transparently—materials, fabrication processes, inspection protocols, logistics, everything. Hidden costs that surface later often exceed any initial savings from choosing the cheapest option.

Sustainability considerations also factor in increasingly. How do suppliers manage waste? What about emissions and energy efficiency? ISO 14001 certification signals these practices are already embedded in operations, not just aspirational marketing language.

Why This Evaluation Process Matters

Saudi Arabia’s construction sector doesn’t wait around. NEOM, Qiddiya, The Red Sea Global—these projects set benchmarks not just regionally but globally. The structural steel fabrication in Saudi Arabia supporting these developments needs fabrication partners operating at comparable standards.

Companies with documented portfolios across major UAE developments and internationally recognized certifications have proven they can deliver precision at scale while maintaining safety standards. That track record directly translates into reliability for Saudi projects.

When timelines are compressed, quality expectations are high, and there’s minimal room for error, past performance becomes the best predictor of future results.

Making an Informed Decision

You need to do more than just compare bids when picking a structural steel fabrication company in Saudi Arabia. It’s about finding a team that always delivers accuracy, keeps operations open, and puts performance that lasts beyond the end of the project first.

Strong fabricators stand out through:

- Active quality and safety certifications (ISO 9001:2025, ISO 45001:2018, ISO 14001:2015)

- Proven experience with technically complex, large-scale steel structures

- Comprehensive in-house capabilities covering design through installation

- Clear communication standards and documented on-time delivery

Kingston Technical Contracting LLC operates according to these standards throughout the GCC. With current certifications, cross-border compliance, and established engineering expertise, Kingston delivers reliable structural steel fabrication for projects requiring strength, precision, and quality that endures—serving developments across Saudi Arabia, the UAE, and the broader region.

The right fabrication partner doesn’t just supply steel components. They integrate into project teams, contribute technical knowledge throughout execution, and ensure that what gets designed actually gets built to specification. That partnership approach makes the difference between projects that succeed and projects that struggle.