Need Reliable Steel Fabrication Supply from UAE to Africa? Here's What You Should Know

Here’s something every project manager knows: your steel fabrication supplier can either be your biggest asset or your worst nightmare. Miss a delivery deadline, get substandard quality, or deal with fabrication errors—and suddenly your entire project timeline is in jeopardy.

If you’re managing construction or infrastructure projects in Africa, you’ve probably faced this challenge. Finding reliable steel Fabrication Supply from UAE to Africa isn’t just about getting metal delivered. It’s about finding a partner who understands what’s at stake and has the track record to back up their promises.

That’s exactly what Kingston Technical Contracting L.L.C. has built its reputation on. Kingston have spent years handling some of the UAE’s most challenging projects, and now they’re bringing that expertise to African markets.

Why UAE Makes Sense as Your Steel Source

Look at a map and you’ll see why the UAE has become such a critical link for African infrastructure projects. It sits right between Asia, Europe, and Africa—which isn’t just convenient geography, it’s a massive logistics advantage.

Jebel Ali Port and Khalifa Port aren’t just big—they’re consistently ranked among the most efficient ports globally. When you’re shipping heavy steel consignments, that efficiency translates directly into faster delivery times and lower costs. For a project in East or North Africa, sourcing from the UAE often means getting your materials weeks faster than ordering from Asia or Europe.

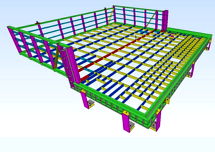

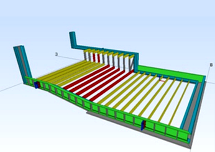

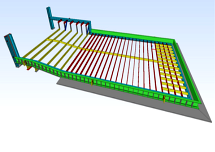

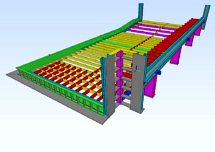

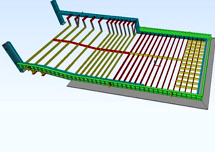

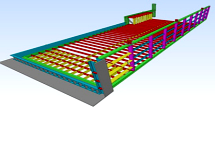

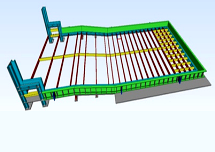

But here’s what really matters beyond location: the UAE has developed serious manufacturing infrastructure. We’re not talking about basic fabrication shops. These are facilities operating under ISO 9001:2015 and ISO 45001:2018 certifications, with quality control processes that match what you’d find in Europe or North America.

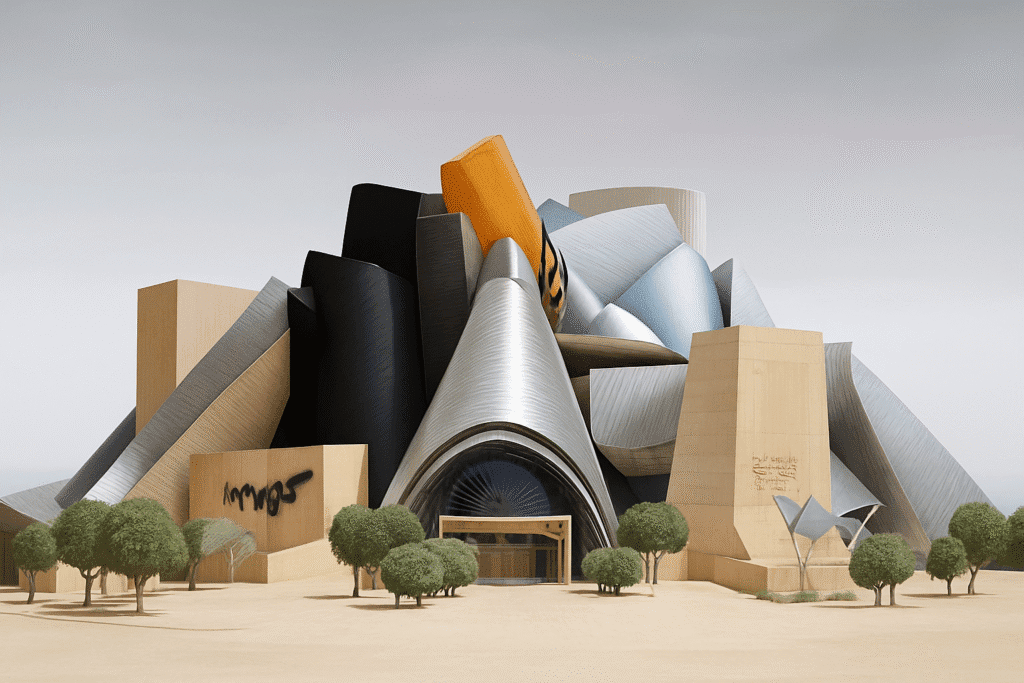

And the range of what they can produce? That’s where UAE suppliers really shine. Need heavy structural steel for a power plant? They’ve got it. Custom fabrication for a commercial tower with complex architectural features? No problem. This versatility is crucial when you’re working across different African markets, each with its own specific requirements and conditions.

For African contractors dealing with tight budgets and tighter timelines, steel fabrication supply from UAE to Africa has become less of an option and more of a strategic choice. The combination of proximity, quality, and capability is hard to replicate from other supply sources.

Kingston’s Foundation: Experience You Can Verify

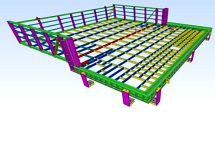

Kingston Technical Contracting L.L.C. operates out of Dubai with licenses in Dubai, Sharjah, and Abu Dhabi. That multi-emirate presence isn’t just paperwork—it gives them manufacturing flexibility and logistics options that single-location operators can’t match.

Their certifications tell you something important about how they operate:

- ISO 9001:2015 means they have documented quality management systems, not just claims about quality

- ISO 14001:2015 shows that environmental management is part of their operations, not an afterthought

- ISO 45001:2018 demonstrates systematic occupational health and safety protocols

If you’ve ever dealt with international projects, you know these certifications matter. They’re not guarantees that nothing will ever go wrong, but they mean there are systems in place to catch issues before they become problems. For cross-border Steel Fabrication Supply from UAE to Africa, having a supplier with documented processes makes everything smoother—from quality verification to customs documentation to client reporting.

Real Projects, Real Results

Anyone can build a nice website and claim expertise. Kingston’s actual project portfolio tells a different story. These are projects you can verify, with tonnages and timelines that demonstrate real capability.

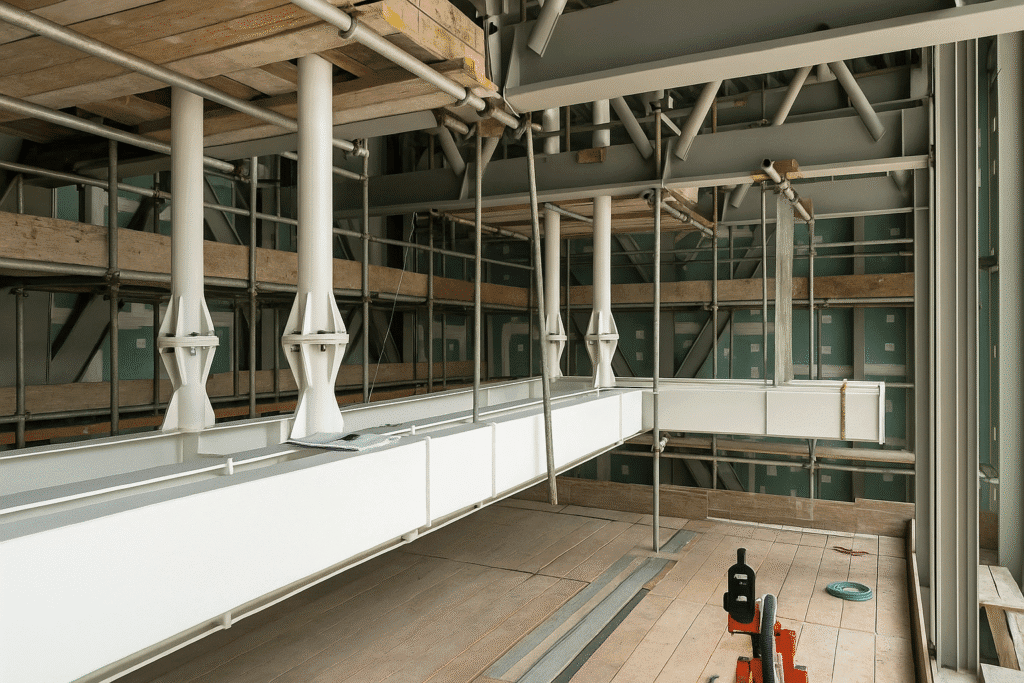

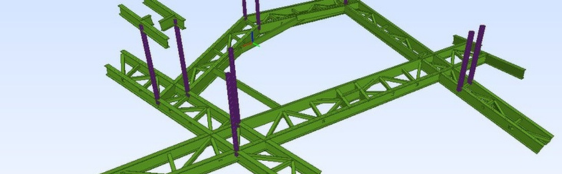

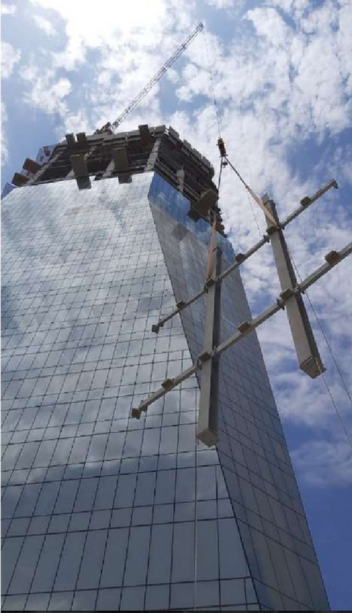

The Royal Atlantis Resort and Residences

Walking into the Royal Atlantis, most people see luxury. Engineers see the structural steel fabrication complexity that made that luxury possible. Kingston fabricated and installed 600 tons of steel for this Palm Jumeirah landmark, working with SSANGYONG/BESIX and coordinating with SIXCO as the main contractor.

The challenge wasn’t just the tonnage—it was maintaining precision across components that had to meet both engineering specs and architectural finishing standards. In a project where the steel would be partially visible in the final design, there’s no hiding mistakes. Everything had to be right the first time.

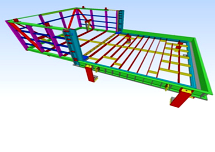

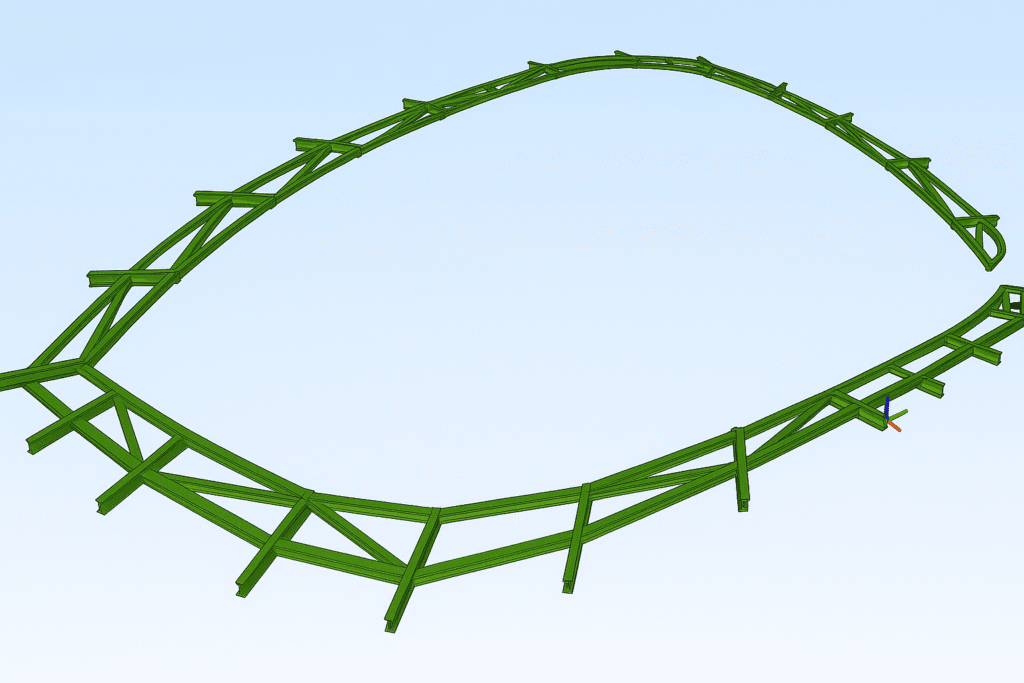

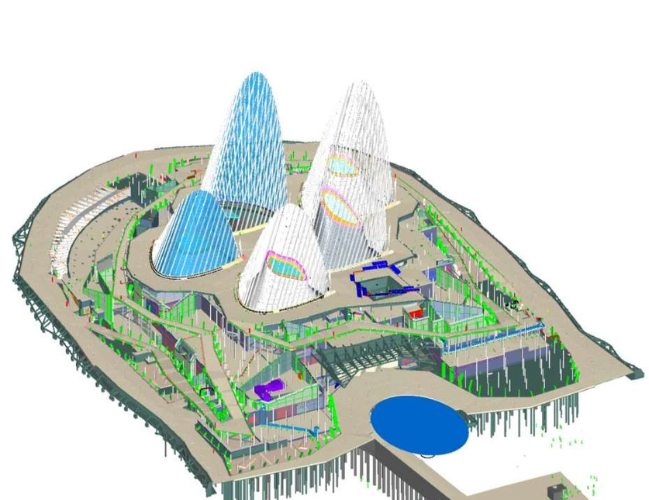

Guggenheim Abu Dhabi

Cultural buildings present unique challenges. The Guggenheim required 600 tons of complex secondary steelwork with tolerances that would make a shipbuilder nervous. Working with DMCC and WSP Consultants, Kingston delivered components where millimeter-level accuracy wasn’t optional.

This is the kind of project that separates fabricators who can follow standard drawings from those who can handle genuine engineering complexity. The intricate geometries and surface finish requirements demanded both technical expertise and quality control that doesn’t compromise.

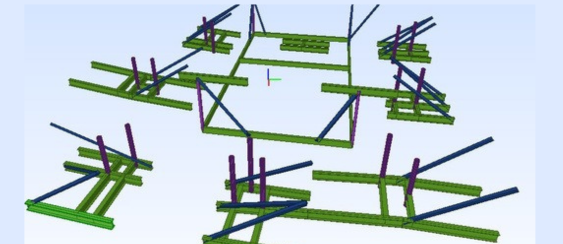

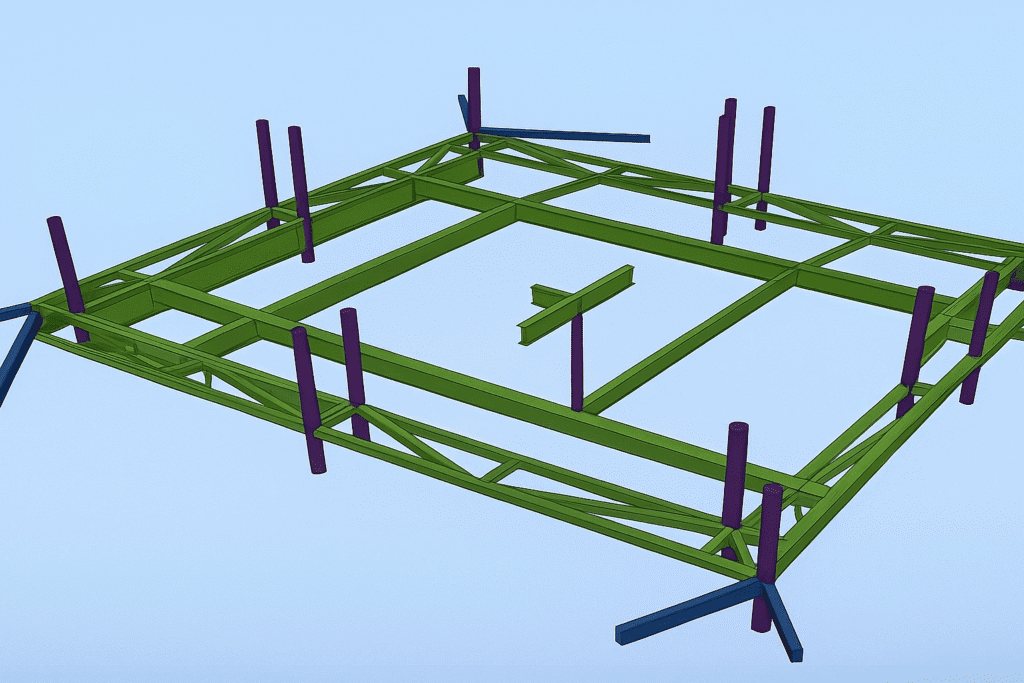

Zayed National Museum

At 1,200 tons, this was Kingston’s largest involvement in these landmark projects. But it wasn’t just about volume—it was about national significance. The Zayed National Museum represents UAE’s cultural heritage, coordinated by the Department of Culture and Tourism, with no margin for anything less than excellence.

Every connection design, every fabricated component had to meet museum-grade standards. This level of scrutiny in fabrication and assembly is exactly what you want to see from a supplier handling critical infrastructure projects. If they can deliver for a national monument, they can handle your project requirements.

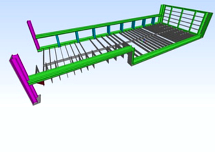

Uptown Dubai Phase 1

Large mixed-use developments test a different capability: consistency across time. Kingston delivered 850 tons for this DMCC project, maintaining quality and schedule through multiple construction phases.

This matters more than you might think. Any fabricator can do quality work on a single batch. Maintaining that quality and delivery reliability across months of ongoing production—that’s what separates reliable suppliers from one-time performers. For African projects that often involve phased construction, this consistency is critical.

What African Projects Actually Need

Kingston’s UAE experience directly addresses what makes African infrastructure projects challenging. Here’s what they bring to the table:

Established export operations. They’re not learning how to ship to Africa on your project. They’ve got logistics partners, understand port procedures, and have refined the documentation processes that can slow down first-time exporters. When they quote a delivery timeline, they’re basing it on actual experience, not optimistic estimates.

Complete control over the fabrication chain. From design through coating and delivery, everything happens in-house or under direct supervision. You’re not dealing with a middleman coordinating multiple subcontractors. This matters enormously when issues come up—and they always do—because there’s one clear point of accountability and decision-making.

Quality systems that speak the international language. Those ISO certifications mean their quality documentation works with international project requirements. If you need third-party inspection, material certifications, or compliance verification for project financing, you’re not starting from scratch explaining what’s needed.

Real versatility across building types. Their portfolio spans luxury resorts, cultural institutions, commercial developments, and mixed-use projects. This isn’t a shop that only knows how to do one type of steel. Whether you’re building industrial infrastructure or a commercial tower, they’ve tackled similar engineering challenges.

The infrastructure to handle scale. Multi-emirate operations give them production capacity that matters for larger projects. If your African development needs significant tonnage delivered across multiple phases, they have the manufacturing footprint to handle it without overextending.

Building Connections That Matter

Africa’s construction sector is expanding rapidly. Energy projects, transportation infrastructure, commercial developments—the demand for quality steel is only growing. But growth creates its own challenges, particularly around supply chain reliability.

What makes Steel Fabrication Supply from UAE to Africa attractive isn’t just the steel itself. It’s the reliability that comes with established infrastructure, proven processes, and verifiable experience.

Kingston’s work on projects like the Zayed National Museum and Royal Atlantis demonstrates something important: they can handle complexity and deliver on commitments when the stakes are high. That’s the kind of track record that translates well to African infrastructure projects where delays cost money and quality issues create safety risks.

Their Dubai base offers practical advantages beyond just geography. The UAE has invested heavily in ports, logistics networks, and quality infrastructure that make complex export operations manageable. Combined with Kingston’s documented project execution capability, African contractors get more than a supplier—they get a partner who understands project pressures and has systems in place to meet them.

In infrastructure development, you’re only as strong as your supply chain’s weakest link. When that supply chain includes structural steel—the literal backbone of most projects—choosing the right supplier isn’t just important, it’s fundamental.

Kingston Technical Contracting L.L.C. brings proven UAE engineering capability to African infrastructure development. They’re not experimenting with export markets or learning fabrication quality on your project. They’re applying experience earned on some of the region’s most demanding builds to help African projects succeed.

From major landmarks in the Emirates to growing infrastructure needs across Africa, they’re focused on one thing: delivering the precision, quality, and reliability that serious projects require. Because at the end of the day, that’s what builds trust—and what keeps projects moving forward.